The pioneer and leading developer of Surfacing Alloys for the Glass Container industry, Wall Colmonoy has been protecting and restoring glass parts for over 85 years

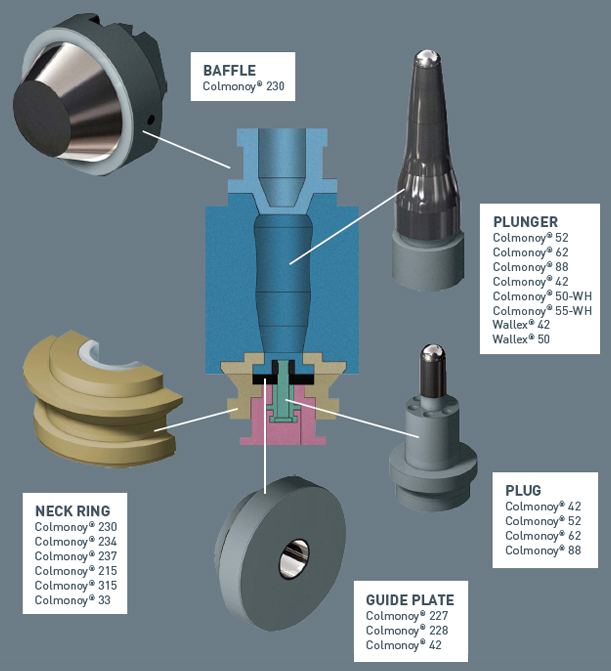

Wall Colmonoy provides specially formulated wear-resistant Colmonoy® (nickel-based) and Wallex® (cobalt-based) Surfacing Alloys including Tungsten Carbide Composite alloys for Plunger Manufacture.

Wall Colmonoy also manufactures equipment to apply Colmonoy®, Wallex®, or other hard surfacing alloys. Wall Colmonoy’s Fusewelder™ Torch and Spraywelder™ System were specially developed to extend the service life of glass components.

Wall Colmonoy also produces engineered cast or fully machined glass mould components designed to optimise wear, corrosion, abrasion and heat resistant properties. Visit Precision Components for more information.

Range of alloys specifically designed for the Glass Container Industry for repair and protection of glass moulds.

After decades of extensive research and field tests, Wall Colmonoy developed a new generation of wear-resistant alloys specially formulated for the glass container industry.

Colmonoy® surfacing alloys are nickel-based powders containing special wetting agents which produce high bond-strength deposits with virtually no overspray adherence. The alloys provide porosity-free, low coefficient-of-friction finishes for producing high-quality glass products.

Colmonoy® alloys bond to most base metals including cast iron, carbon steels, stainless steels, aluminium-bronze alloys and nickel. The extremely low application temperature permits faster and easier weld overlays.

Available as Fusewelder™ powder for application with Wall Colmonoy’s Fusewelder™ Torch. Colmonoy® alloys are effective on a variety of components.

Colmonoy® alloys produce high-quality glass products:

Baffles, Neck Rings, Guide Plates, Plugs, Blow Heads, Funnel, Guide Rings, Guide Plates, Plungers – Blow-and-Blow Plunger, Press-and-Blow Plunger, Pressware Plunger, Narrow-Neck Plunger

For Glass Mould Castings, visit Precision Components or our sister company, Franklin Bronze Precision Components.

| Precision Components | Franklin Bronze |