Enhancing Real-Time Prediction of Effluent Water Quality of Wastewater Treatment Plant Based on Improved Feedforward Neural Network Coupled with Optimization Algorithm

Abstract

:1. Introduction

2. Materials and Methods

2.1. Study Site Description

2.2. On-Line Data Source

2.3. Motive of Model Structure Design

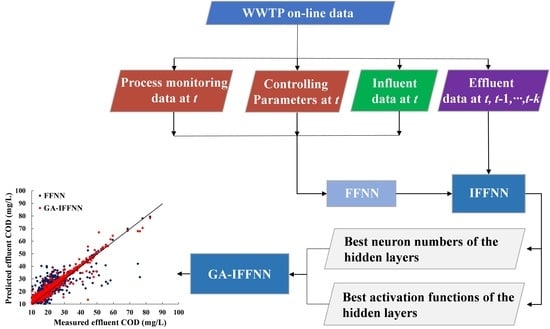

2.4. Modeling Methodology

2.4.1. IFFNN Module

2.4.2. IFFNN Structure Optimization

3. Results and Discussion

3.1. Datasets for ANN Modeling

3.2. Modeling Prediction Performance between FFNN and IFFNN

3.3. Modeling Prediction Performance Based on GA-IFFNN

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| ANN | Artificial neural network |

| ASM | Activated sludge modeling |

| COD | Chemical oxygen demand |

| DO | Dissolved oxygen |

| FFNN | Feedforward neural network |

| GA | Genetic algorithm |

| IFFNN | Improved feedforward neural network |

| MAPE | Mean absolute percentage error |

| ML | Machine learning |

| MLSS | Mixed liquor suspended solids |

| NH3-N | Ammonia |

| ORP | Oxidation–reduction potential |

| R2 | The coefficient of determination |

| TN | Total nitrogen |

| TP | Total phosphorus |

| WWTP | Wastewater treatment plant |

References

- Filipe, J.; Bessa, R.J.; Reis, M.; Alves, R.; Povoa, P. Data-driven predictive energy optimization in a wastewater pumping station. Appl. Energy. 2019, 252, 113423. [Google Scholar] [CrossRef] [Green Version]

- Plappally, A.K.; Lienhard, V.J.H. Energy requirements for water production, treatment, end use, reclamation, and disposal. Renew. Sustain. Energy Rev. 2012, 16, 4818–4848. [Google Scholar] [CrossRef]

- Reifsnyder, S.; Garrido-Baserba, M.; Cecconi, F.; Wong, L.; Ackman, P.; Melitas, N.; Rosso, D. Relationship between manual air valve positioning, water quality and energy usage in activated sludge processes. Water Res. 2020, 173, 115537–115550. [Google Scholar] [CrossRef]

- Singh, P.; Carliell-Marquet, C.; Kansal, A. Energy pattern analysis of a wastewater treatment plant. Appl. Water Sci. 2012, 2, 221–226. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Z.; Kusiak, A.; Zeng, Y.; Wei, X. Modeling and optimization of a wastewater pumping system with data-mining methods. Appl. Energy 2016, 164, 303–311. [Google Scholar] [CrossRef]

- Calise, F.; Eicker, U.; Schumacher, J.; Vicidomini, M. Wastewater Treatment Plant: Modelling and validation of an activated Sludge Process. Energies 2020, 13, 3925. [Google Scholar] [CrossRef]

- Jaramillo, F.; Orchard, M.; Munoz, C.; Zamorano, M.; Antileo, C. Advanced strategies to improve nitrification process in sequencing batch reactors—A review. J. Environ. Manag. 2016, 218, 154–164. [Google Scholar] [CrossRef]

- Bach, P.M.; Rauch, W.; Mikkelsen, P.S.; McCarthy, D.T.; Deletic, A. A critical review of integrated urban water modelling-urban drainage and beyond. Environ. Modell. Softw. 2014, 54, 88–107. [Google Scholar] [CrossRef]

- Rauch, W. Groundbreaking papers in Water Research 1967–2006. Water Res. 2006, 40, 3149. [Google Scholar] [CrossRef]

- Henze, M.; Grady, C.P.L., Jr.; Gujer, W.; Marais, G.V.R.; Matsuo, T. A general model for single-sludge wastewater treatment systems. Water Res. 1987, 21, 505–515. [Google Scholar] [CrossRef] [Green Version]

- Chen, L.; Tian, Y.; Cao, C.; Zhang, S.; Zhang, S. Sensitivity and uncertainty analyses of an extended ASM3-SMP model describing membrane bioreactor operation. J. Membr. Sci. 2012, 389, 99–109. [Google Scholar] [CrossRef]

- Gujer, W.; Henze, M.; Mino, T.; Loosdrecht, M. Activated sludge model no. 3. Water Sci. Technol. 1999, 39, 183–193. [Google Scholar] [CrossRef]

- Henze, M.; Gujer, W.; Mino, T.; Matsuo, T.; Wentzel, M.; Marais, G. Wastewater and biomass characterization for the activated sludge model no. 2 biological phosphorus removal. Water Sci. Technol. 1995, 31, 13–23. [Google Scholar] [CrossRef]

- Busch, J.; Elixmann, D.; Kühl, P.; Gerkens, C.; Schlöder, J.P.; Bock, H.G.; Marquardt, W. State estimation for large-scale wastewater treatment plants. Water Res. 2013, 47, 4774–4787. [Google Scholar] [CrossRef]

- Diehl, S.; Faras, S. Control of an ideal activated sludge process in wastewater treatment via an ODE–PDE model. J. Process Control 2013, 23, 359–381. [Google Scholar] [CrossRef] [Green Version]

- Long, S.; Zhao, L.; Liu, H.; Li, J.; Zhou, X.; Liu, Y.; Qiao, Z. A Monte Carlo-based integrated model to optimize the cost and pollution reduction in wastewater treatment processes in a typical comprehensive industrial park in China. Sci. Total Environ. 2019, 647, 1–10. [Google Scholar] [CrossRef]

- Moral, H.; Aksoy, A.; Gokcay, C.F. Modeling of the activated sludge process by using artificial neural networks with automated architecture screening. Comput. Chem. Eng. 2008, 32, 2471–2478. [Google Scholar] [CrossRef]

- Huang, R.; Ma, C.; Ma, J.; Huangfu, X.; He, Q. Machine learning in natural and engineered water systems. Water Res. 2021, 205, 117666–117689. [Google Scholar] [CrossRef]

- Zhao, L.; Dai, T.; Qiao, Z.; Sun, P.; Hao, J.; Yang, K. Application of artificial intelligence to wastewater treatment: A bibliometric analysis and systematic review of technology, economy, management, and wastewater reuse. Process Saf. Environ. Protect. 2020, 133, 169–182. [Google Scholar] [CrossRef]

- Zhao, X.; Xu, T.; Ye, Z.; Liu, W. A TensorFlow-based new high-performance computational framework for CFD. J. Hydrodyn. 2020, 32, 735–746. [Google Scholar] [CrossRef]

- Kadkhodazadeh, M.; Valikhan Anaraki, M.; Morshed-Bozorgdel, A.; Farzin, S. A new methodology for reference evapotranspiration prediction and uncertainty analysis under climate change conditions based on machine learning, multi criteria decision making and Monte Carlo methods. Sustainability 2022, 14, 2601. [Google Scholar] [CrossRef]

- Rashid Niaghi, A.; Hassanijalilian, O.; Shiri, J. Estimation of reference evapotranspiration using spatial and temporal machine learning approaches. Hydrology 2021, 8, 25. [Google Scholar] [CrossRef]

- Kadkhodazadeh, M.; Farzin, S. A novel LSSVM model integrated with GBO algorithm to assessment of water quality parameters. Water Resour. Manag. 2021, 35, 3939–3968. [Google Scholar] [CrossRef]

- Antwi, P.; Zhang, D.C.; Xiao, L.W.; Kabutey, F.T.; Quashie, F.K.; Luo, W.H.; Meng, J.; Li, J.Z. Modeling the performance of Single-stage Nitrogen removal using anammox and partial nitritation (SNAP) process with backpropagation neural network and response surface methodology. Sci. Total Environ. 2019, 690, 108–120. [Google Scholar] [CrossRef]

- Hamed, M.M.; Khalafallah, M.G.; Hassanien, E.A. Prediction of wastewater treatment plant performance using artificial neural networks. Environ. Modell. Softw. 2004, 19, 919–928. [Google Scholar] [CrossRef]

- Man, Y.; Hu, Y.; Ren, J. Forecasting COD load in municipal sewage based on ARMA and VAR algorithms. Resour. Conserv. Recycl. 2019, 144, 56–64. [Google Scholar] [CrossRef]

- Mandal, S.; Mahapatra, S.S.; Sahu, M.K.; Patel, R.K. Artificial neural network modelling of As (III) removal from water by novel hybrid material. Process Saf. Environ. Prot. 2015, 93, 249–264. [Google Scholar] [CrossRef]

- Reynel-Avila, H.E.; Bonilla-Petriciolet, A.; de la Rosa, G. Analysis and modeling of multicomponent sorption of heavy metals on chicken feathers using Taguchi’s experimental designs and artificial neural networks. Desalin. Water Treat. 2015, 55, 1885–1899. [Google Scholar] [CrossRef]

- Zhang, W.; Tooker, N.B.; Mueller, A.V. Enabling wastewater treatment process automation: Leveraging innovations in real-time sensing, data analysis, and online controls. Environ. Sci.: Wat. Res. Technol. 2020, 6, 2973–2992. [Google Scholar] [CrossRef]

- Giwa, A.; Daer, S.; Ahmed, I.; Marpu, P.R.; Hasan, S.W. Experimental investigation and artificial neural networks ANNs modeling of electrically-enhanced membrane bioreactor for wastewater treatment. J. Water Process Eng. 2016, 11, 88–97. [Google Scholar] [CrossRef]

- Khatri, N.; Khatri, K.K.; Sharma, A. Prediction of effluent quality in ICEAS sequential batch reactor using feedforward artificial neural network. Water Sci. Technol. 2019, 80, 213–222. [Google Scholar] [CrossRef]

- Yang, S.-S.; Yu, X.-L.; Ding, M.-Q.; He, L.; Cao, G.-L.; Zhao, L.; Tao, Y.; Pang, J.-W.; Bai, S.-W.; Ding, J.; et al. Simulating a combined lysis-cryptic and biological nitrogen removal system treating domestic wastewater at low C/N ratios using artificial neural network. Water Res. 2021, 189, 116576. [Google Scholar] [CrossRef]

- Nourani, V.; Asghari, P.; Sharghi, E. Artificial intelligence based ensemble modeling of wastewater treatment plant using jittered data. J. Clean. Prod. 2021, 291, 125772. [Google Scholar] [CrossRef]

- Sharghi, E.; Nourani, V.; AliAshrafi, A.; Gokcekus, H. Monitoring effluent quality of wastewater treatment plant by clustering based artificial neural network method. Desalination Water Treat. 2019, 164, 86–97. [Google Scholar] [CrossRef]

- Mahmod, N.; Wahab, N.A. Dynamic modelling of aerobic granular sludge artificial neural networks. Int. Jo. Electr. Comput. Eng. 2017, 7, 1568–1573. [Google Scholar] [CrossRef]

- Yu, P.; Cao, J.; Jegatheesan, V.; Du, X. A real-time BOD estimation method in wastewater treatment process based on an optimized extreme learning machine. Appl. Sci. 2019, 9, 523. [Google Scholar] [CrossRef] [Green Version]

- Al Aani, S.; Bonny, T.; Hasan, S.W.; Hilal, N. Can machine language and artificial intelligence revolutionize process automation for water treatment and desalination? Desalination 2019, 458, 84–96. [Google Scholar] [CrossRef]

- Zhao, Z.; Yin, H.; Xu, Z.; Peng, J.; Yu, Z. Pin-pointing groundwater infiltration into urban sewers using chemical tracer in conjunction with physically based optimization model. Water Res. 2020, 175, 115689–115698. [Google Scholar] [CrossRef]

- Badrnezhad, R.; Mirza, B. Modeling and optimization of cross-flow ultrafiltration using hybrid neural network-genetic algorithm approach. J. Ind. Eng. Chem. 2014, 20, 528–543. [Google Scholar] [CrossRef]

- Ren, F.; Hu, H.; Tang, H. Active flow control using machine learning: A brief review. J. Hydrodyn. 2020, 32, 247–253. [Google Scholar] [CrossRef]

- Schubert, M.; Muffler, A.; Mourad, S. The use of a radial basis neural network and genetic algorithm for improving the efficiency of laccase-mediated dye decolourization. J. Biotechnol. 2012, 161, 429–436. [Google Scholar] [CrossRef]

- Fernandez de Canete, J.; del Saz-Orozco, P.; Gómez-de-Gabriel, J.; Baratti, J.; Ruano, A.; Rivas-Blanco, I. Control and soft sensing strategies for a wastewater treatment plant. Comput. Chem. Eng. 2021, 144, 107146. [Google Scholar] [CrossRef]

- Huang, M.; Wei, H.; Wan, J.; Ma, Y.; Chen, X. Multi-objective optimisation for design and operation of anaerobic digestion using GA-ANN and NSGA-II. J. Chem. Technol. Biotechnol. 2016, 91, 226–233. [Google Scholar] [CrossRef]

- Lotfi, K.; Bonakdari, H.; Ebtehaj, I.; Mjalli, F.S.; Zeynoddin, M.; Delatolla, R.; Gharabaghi, B. Predicting wastewater treatment plant quality parameters using a novel hybrid linear-nonlinear methodology. J. Environ. Manag. 2019, 240, 463–474. [Google Scholar] [CrossRef]

- Ghaderpour, E.; Pagiatakis, S.D.; Hassan, Q.K. A survey on change detection and time series analysis with applications. Appl. Sci. 2021, 11, 6141. [Google Scholar] [CrossRef]

- Dairi, A.; Cheng, T.; Harrou, F.; Sun, Y.; Leiknes, T. Deep learning approach for sustainable WWTP operation: A case study on data-driven influent conditions monitoring. Sustain. Cities Soc. 2019, 50, 101670. [Google Scholar] [CrossRef]

- Qiao, J.; Huang, X.; Han, H. Recurrent neural network-based control for wastewater treatment process. In Proceedings of the Advances in Neural Networks—ISNN 2012; Springer: Berlin/Heidelberg, Germany, 2012; pp. 496–506. [Google Scholar]

- Zhang, Y.; Gao, X.; Smith, K.; Inial, G.; Liu, S.; Conil, L.B.; Pan, B. Integrating water quality and operation into prediction of water production in drinking water treatment plants by genetic algorithm enhanced artificial neural network. Water Res. 2019, 164, 114888–114899. [Google Scholar] [CrossRef]

- Chakraborty, T.; Chakraborty, A.K.; Chattopadhyay, S. A novel distribution-free hybrid regression model for manufacturing process efficiency improvement. J. Comput. Appl. Math. 2019, 362, 130–142. [Google Scholar] [CrossRef] [Green Version]

- Asadi, A.; Verma, A.; Yang, K.; Mejabi, B. Wastewater treatment aeration process optimization: A data mining approach. J. Environ. Manag. 2017, 203, 630–639. [Google Scholar] [CrossRef]

- Abrahart, R.J.; Dawson, C.W.; See, L.M.; Mount, N.J.; Shamseldin, A.Y. Discussion of “Evapotranspiration modelling using support vector machines”. Hydrol. Sci. J. 2010, 55, 1442–1450. [Google Scholar] [CrossRef]

- Maier, H.R.; Jain, A.; Dandy, G.C.; Sudheer, K.P. Methods used for the development of neural networks for the prediction of water resource variables in river systems: Current status and future directions. Environ. Model. Softw. 2010, 25, 891–909. [Google Scholar] [CrossRef]

- Xiong, Z.; Cui, Y.; Liu, Z.; Zhao, Y.; Hu, M.; Hu, J. Evaluating explorative prediction power of machine learning algorithms for materials discovery using k-fold forward cross-validation. Comp. Mater. Sci. 2020, 171, 109203. [Google Scholar] [CrossRef]

- Steele, G.L., Jr.; Vigna, S. LXM: Better Splittable Pseudorandom Number Generators (and Almost as Fast). Proc. ACM Program. Lang. 2021, 5, 1–31. [Google Scholar] [CrossRef]

| No. | Parameters | Unit | Ave. | Standard Deviation | Max. | Min. | Grade 1-A Discharge Standard |

|---|---|---|---|---|---|---|---|

| 1 | Influent COD | mg/L | 320 | 92.9 | 796 | 70.1 | / |

| 2 | Influent NH3-N | mg/L | 22.3 | 3.67 | 30.0 | 15.1 | / |

| 3 | Influent TN | mg/L | 49.0 | 7.57 | 59.9 | 30.1 | / |

| 4 | Influent TP | mg/L | 3.45 | 1.08 | 8.86 | 1.31 | / |

| 5 | pH | / | 7.70 | 0.49 | 9.25 | 6.86 | / |

| 6 | Effluent COD | mg/L | 19.5 | 7.56 | 82.5 | 7.88 | 50 |

| 7 | Effluent NH3-N | mg/L | 0.10 | 0.01 | 0.15 | 0.06 | 5 (8) 1 |

| 8 | Effluent TN | mg/L | 8.67 | 1.74 | 13.3 | 4.05 | 15 |

| 9 | Effluent TP | mg/L | 0.12 | 0.03 | 0.20 | 0.03 | 0.5 |

| (a) COD | ||||||

| Modeling Type | Time of Effluent Data Input (h) | ANN Structure | Training Dataset | Test Dataset | ||

| MAPE | R2 | MAPE | R2 | |||

| FFNN | 1 | a) 86-86-86-1 | 6.3% | 0.84 | 22.0% | 0.20 |

| b) Relu6-Relu6 | ||||||

| IFFNN | 1 | a) 90-90-90-1 | 4.9% | 0.92 | 16.8% | 0.47 |

| b) Relu6- Relu6 | ||||||

| GA-IFFNN | 1 | a) 90-160-180-1 | 3.7% | 0.95 | 13.0% | 0.63 |

| b) Relu-Tanh | ||||||

| GA-IFFNN | 25 | a) 186-800-800-1 | 3.6% | 0.95 | 10.5% | 0.76 |

| b) Relu-Tanh | ||||||

| (b) TN | ||||||

| Modeling Type | Time of Effluent Data Input (h) | ANN Structure | Training Dataset | Test Dataset | ||

| MAPE | R2 | MAPE | R2 | |||

| FFNN | 1 | a) 86-86-86-1 | 3.6% | 0.92 | 8.4% | 0.70 |

| b) Relu6-Relu6 | ||||||

| IFFNN | 1 | a) 90-90-90-1 | 2.8% | 0.95 | 4.8% | 0.89 |

| b) Relu6-Relu6 | ||||||

| GA-IFFNN | 1 | a) 90-100-180-1 | 0.6% | 0.99 | 2.6% | 0.97 |

| b) Sigmoid-Relu | ||||||

| GA-IFFNN | 25 | a) 186-200-200-1 | 0.6% | 0.99 | 2.3% | 0.97 |

| b) Sigmoid-Relu | ||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, Y.; Chen, Y.; Lian, Q.; Yin, H.; Peng, J.; Sheng, M.; Wang, Y. Enhancing Real-Time Prediction of Effluent Water Quality of Wastewater Treatment Plant Based on Improved Feedforward Neural Network Coupled with Optimization Algorithm. Water 2022, 14, 1053. https://doi.org/10.3390/w14071053

Xie Y, Chen Y, Lian Q, Yin H, Peng J, Sheng M, Wang Y. Enhancing Real-Time Prediction of Effluent Water Quality of Wastewater Treatment Plant Based on Improved Feedforward Neural Network Coupled with Optimization Algorithm. Water. 2022; 14(7):1053. https://doi.org/10.3390/w14071053

Chicago/Turabian StyleXie, Yifan, Yongqi Chen, Qing Lian, Hailong Yin, Jian Peng, Meng Sheng, and Yimeng Wang. 2022. "Enhancing Real-Time Prediction of Effluent Water Quality of Wastewater Treatment Plant Based on Improved Feedforward Neural Network Coupled with Optimization Algorithm" Water 14, no. 7: 1053. https://doi.org/10.3390/w14071053